Help Restore a One-of-a-Kind Steam Legend – Just a Fiver for the 5!

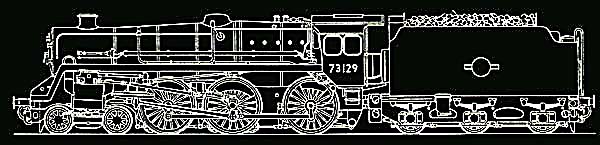

Support the Restoration of BR Standard 5 No. 73129 – the Only Caprotti-Fitted Example

BR Standard 5 No. 73129 isn’t just another steam engine — it’s the only surviving Standard 5 fitted with Caprotti valve gear. A truly unique piece of British engineering history, and right now, it needs your help to steam again.

We’re inviting railway enthusiasts and heritage supporters to join the mission by pledging just £5 a month to help bring this irreplaceable locomotive back to working order. Don’t worry, larger amounts can also be made!

We estimate the restoration will be in the region of £400k.

If we can get 5000 people to donate £5 per month, it would give the project £25k of available funds to allow contractors to start work on the restoration!

Why your help is vital ?

Steam locomotive restoration takes expert skill, time, and significant funding. Every pound goes directly toward specialist work — from boiler repairs to the distinctive Caprotti valve gear that sets 73129 apart.

Why this matters ?

This isn’t just about saving another engine — it’s about preserving the only Caprotti Standard 5 for future generations to marvel at this engineering milestone.

Be part of history — just a Fiver for the 5.

Once funds allow the restoration to begin, supporters will receive regular updates, behind-the-scenes content and the pride of playing a part in this historic locomotive’s future. .

Donate today and help 73129 live on.

It’s just £5 a month — but your impact is priceless.

Please email us @ donations@midlandrailway-butterley.co.uk for details on setting up regular monthly payments to the “Standard Five Fund”

Click Here to make a donation today

Leading Dimensions

Cylinders (2): 19″ diameter x 28″ stroke

Driving wheel diameter: 6ft-2ins

Boiler pressure: 225 lbs per sq. inch

Tractive effort: 26,120 lbs (at 85% boiler pressure)

Length over buffers: 62′-7″ (loco & tender)

Weight of loco in working order: 76tons 0 cwts.

Weight of tender (BR1B): 51 tons 5 cwt (7 tons coal)

Weight of tender (BR1C): 53 tons 5 cwt (9 tons coal)

Water capacity (both types): 4725 gallons

73135-44 were fitted with BR1C tenders, the other Caprotti locos had BR1B tenders.

73129 History

The former British Railway Standard Class 5MT 4-6-0 locomotive no. 73129, now based at the Midland Railway at Butterley, is the sole survivor of the last batch of 30 steam locomotives to be built at Derby Locomotive Works and is unique in being the only preserved Standard Class 5 fitted with Caprotti Valve Gear.

Outshopped from Derby Works in August 1956, it was allocated to Shrewsbury (84G) on the Western Region. In September 1958 it moved north to Patricroft shed (near Manchester), where it was to spend the remainder its working life until being withdrawn from traffic on 2nd December 1967.

It was bought for scrap by Woodham Bros Ltd and towed to their yard at Barry Island in South Wales for cutting up. But apart from having its non-ferrous fittings and pipework removed, and loosing its tender, 73129 remained virtually intact and was subsequently purchased, together with the tender from 75079, by Derby Corporation in 1972 as a potential exhibit for the then embryonic Midland Railway Project.

The 32nd loco to leave Barry Scrapyard for preservation, 73129 was moved by rail back to Derby Loco Works for storage on 6th January 1973, and finally arrived the Midland Railway Centre on 14th February 1975. However, due to other priorities, little was done apart from some conservation and comestic restoration until late in 1993 when, with financial support from the Standard Five Fund, restoration to get 73129 back to full working order, began in earnest.

Caprotti Valve Gear

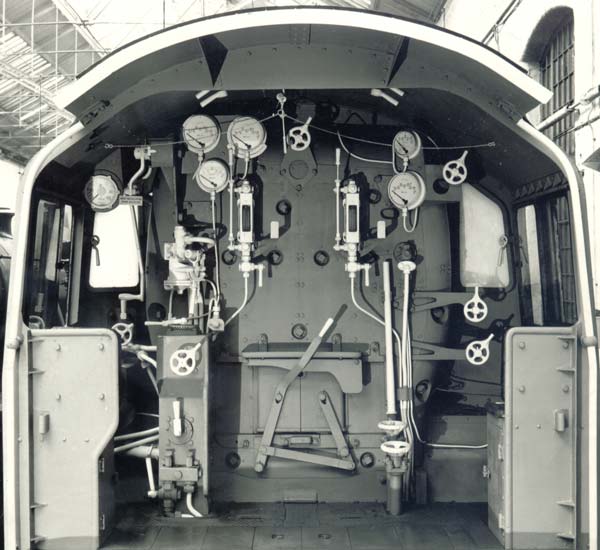

The vast majority of British steam railway locomotives were fitted with either WALSCHAERTS or STEPHENSON valve gear, both of which utilise a series of cranks and levers to actuate PISTON valves to control the admission and exhaust of steam to and from the cylinders.

CAPROTTI valve gear is considerably different in that uses cam actuated POPPET valves (similar to those in an internal combustion engine) to control the flow of steam into and out of the cylinders.

Separate inlet and exhaust valves are fitted at each end of the cylinders and these are actuated by cams enclosed in an oil bath mounted above the cylinders. The rotating cams are are driven through a triple jointed shaft from a worm gearbox mounted on a return crank on the centre driving wheel. The cams push the poppet valves open into cages as required.

A separate gearbox, mounted behind each cylinder and controlled by the driver, allows angular adjustment of the cams to provide an infinitely variable cut-off. The gearbox also advances or retards the cams to allow the locomotive to reverse.

A pilot valve in the regulator admits a supply of saturated steam to the underside of the poppet valves to close them before the main superheated steam reaches the cylinders. When the regulator is closed, the poppet valves automatically open to allow the loco to coast freely.

Invented in the early 1920’s by Italian architect and engineer, Arturo Caprotti, the use of Caprotti valve gear was never widespread in the UK. In the late 1920’s, the LMS experimentally rebuilt 10 ex-LNWR “Claughton” class locomotives with Caprotti valve gear, but in practice, the improved performance (over 20% reduction in coal consumption) did not justify the high initial cost of the gear.

In 1948, in the early days of British Railways, it was decided to build 20 new LMS “Black 5” locomotives (44738 to 44757) with Caprotti valve gear. The totally enclosed mechanism had advantages from the maintenance viewpoint, and although the locomotives were fast and free running, their acceleration was inferior and they were generally regarded as being weaker than their piston valved counterparts.

In 1951, the final two “Black 5” locomotives (44686 and 44687) were built with an improved type of Caprotti valve gear which had been developed in the UK by a private company, Associated Locomotive Engineers, under the leadership of Mr. L.A. Daniels. The British Caprotti valve gear, as it was known, overcame many of the earlier problems and as a result of the experience gained, it was decided to fit it to the new BR Standard Class 8P 4-6-2 no. 71000 Duke of Gloucester, and the final batch of 5MT 4-6-0 locos.

The Standard Class 5 Caprotti locos were particularly fast and free running and speeds of 90mph were not uncommon. One is even reputed to have reached 100mph whilst working a test train. There seems little doubt that had steam locomotive construction continued in the UK, the British Caprotti valve gear would have been extensively used.

History of the Class

A total of 172 Standard Class 5 mixed traffic locomotives were built by British Railways between 1951 and 1957. 73000 to 73099 and 73125 to 73154 were constructed at Derby; 73100 to 73124 and 73155 to 73171 were built at Doncaster. The batch from 73125 to 73154 differed from the remaider of the class by being fitted with Caprotti valve gear as opposed to the Walschaerts valve gear of the other engines.

All the class were fitted with taper boilers, designated as BR type 3 which were virtually identical to the boilers of the Stanier/Ivatt LMS “Black 5” locomotives except for minor alterations to allow the use of standard BR fittings.

The bogie wheels, driving wheels and tender wheels were all fitted with Timken roller bearings.

The initial allocation of the Caprotti locos was as follows:

73125 – 73134 WR Shrewsbury

73135 – 73139 LMR Holyhead

73140 – 73144 LMR Leicester

73145 – 73154 ScR St.Rollox

The Western Region and London Midland Region Caprotti locos were all eventually concentrated at Patricroft, but in the interim period, a number of the LM locomotives were based at Derby, Rowsley and Nottingham.

All the Scottish Region locos remained north of the border but some were eventually dispersed to Ayr, Stirling, Kilmarnock, Motherwell and Polmadie.

It was one of the Scottish locos, 73147, that was the first to be withdrawn from service on August 1965 after a scandalously short life of just 8½ years. Less than three years later, all 30 Caprotti locos had disappeared. Amongst the last to go was the first one of the batch, 73125, which was then just 12 years old when it was withdrawn, along with 73133, 73134 and 73143 when Patricroft shed closed at the end of June 1968.

Build and Withdrawl Dates

73125 07/56 07/68 73135 10/56 04/68 73145 01/57 11/66

73126 08/56 04/68 73136 11/56 03/68 73146 02/57 12/65

73127 08/56 11/67 73137 11/56 06/67 73147 02/57 08/65

73128 08/56 05/68 73138 11/56 05/68 73148 03/57 09/65

73129 08/56 12/67 73139 11/56 05/67 73149 03/57 12/66

73130 09/56 09/67 73140 12/56 10/57 73150 04/57 12/66

Gift Aid

UK Taxpayers can include a gift aid declaration. Through the gift aid scheme for every pound you donate we can claim and extra 25 Pence e.g. A £20 donation is worth £25 with gift aid and is at no extra cost to yourself.